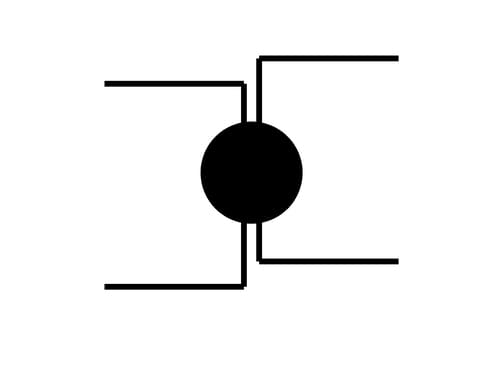

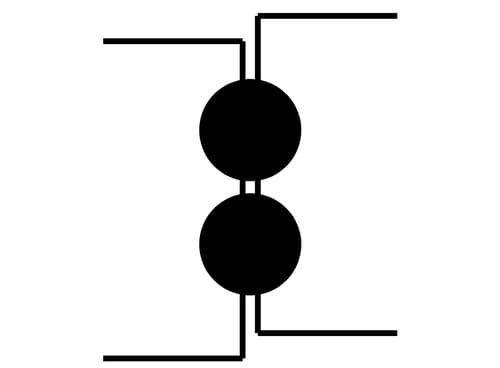

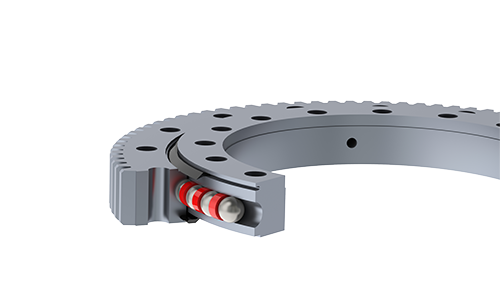

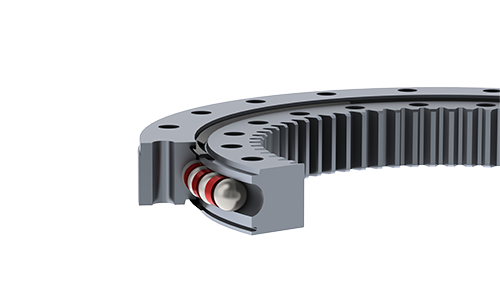

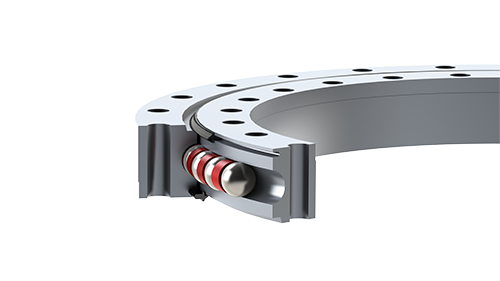

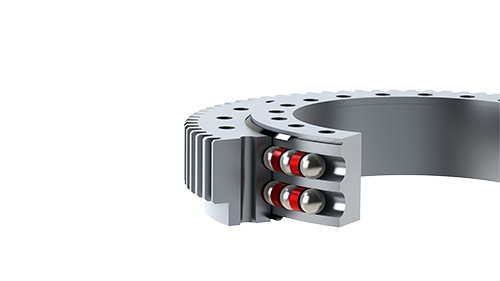

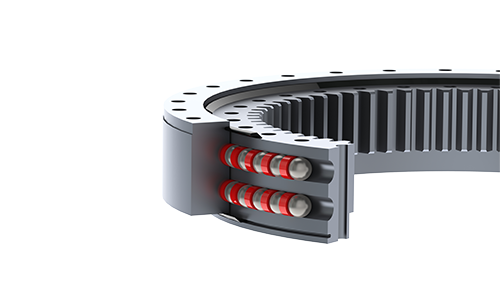

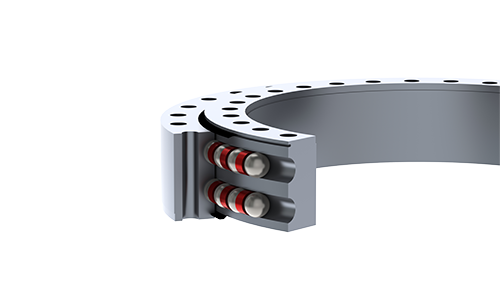

Our standard ball range includes all our single-row and double-row ball slewing bearings.

A distinction must be made between thin sections and standard series. Thin sections have a lower preload in relation to their diameter. They are considered thin because the ratio of cross-section to diameter is low.

Flash-butt welding

Flash-butt welding Precision machining and grinding

Precision machining and grinding  Press quenching

Press quenching Induction heat treatment

Induction heat treatment  Special processes

Special processes