Studies and design

Within the Defontaine Group we manage your industrial projects

- Home

- >

- Studies and design

Study and design of your industrial projects

Within the Defontaine Group, we offer our expertise in the industrial world and production processes to provide you with solutions adapted to your requirements.

Our team will offer guidance for your projects from design to manufacture while providing innovative and functional ideas. We also have several test benches specially dedicated to testing our Rollix slewing rings in real conditions.

Our areas of expertise

The design process for your industrial projects consists in several steps:

- Technical and financial study of the project

- 3D CAD design and drafting

- Design calculations

- Development of component specifications

- Development of rapid and functional prototypes

For your old parts, we offer:

- Inspection of your old parts

- Optimisation based on our expertise

Methods preparation includes:

- Monitoring of market-specific standards

- Creation of manufacturing processes

- Definition and production of manufacturing tools

- Support for operations performed by our technicians in the field

Rollix test benches

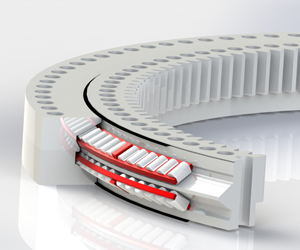

Based on our long-term experience complying with the high standards of the wind energy sector, we have developed our own test benches to ensure the optimum strength of our slewing rings, from the largest (>6,000 mm diameter) to the smallest (100 mm).

The Defontaine Group’s test benches are recognised by our customers and used for the Rollix brand slewing rings in all activities:

Our test benches allow us to test and validate the conformity of our designs and manufacturing processes. Our software allows our teams to perform calculations and record measurement results with micron-level accuracy. Test benches are essential and are used on a daily basis in the development of a product or a project, whether made to order or tailor-made.

These test benches make it possible to guarantee compliance with the requirements and standards of our various markets.

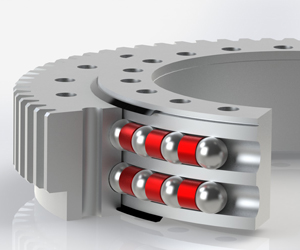

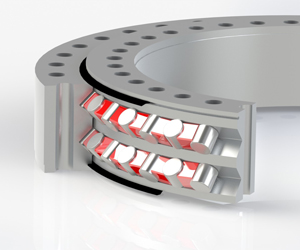

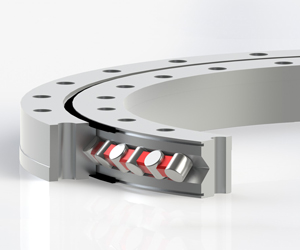

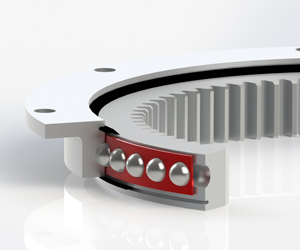

Design examples