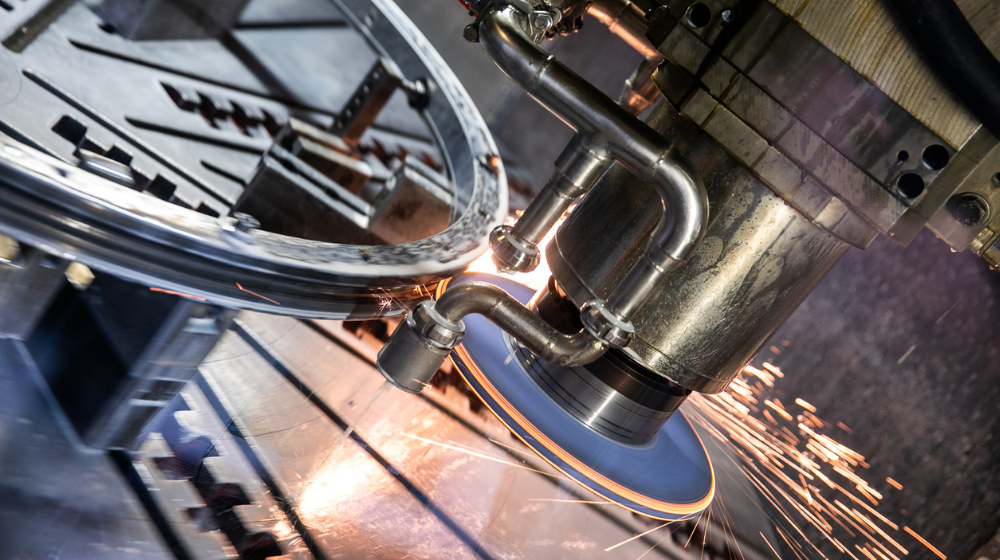

Our precision grinding process

First, surface or cylindrical grinding is a finishing machining process that aims to produce high-quality, high-precision metal parts in the micron range. It involves the removal of very small amounts of material using an abrasive wheel or a tool and is performed using grinding machines of different types:

- Surface grinders, used for grinding flat surfaces

- Cylindrical grinders, used for grinding cylindrical surface

- Internal grinders, used for grinding internal surfaces of cylindrical objects

- Centreless grinders, used for grinding cylindrical parts without a centre support

We can distinguish different steps in this process.

Set up

According to the required specifications, the workpiece is secured and the grinding machine is set up. Based on the material and desired finish, the abrasive wheel is selected

Grinding

The abrasive wheel rotates at high speed and comes into contact with the workpiece, removing material through friction and abrasion. The process is controlled to ensure precise dimensions and surface finish.

Finishing

Depending on the requirements, multiple passes may be made with finer abrasive wheels to achieve the desired surface finish and tolerances.

Inspection

After grinding, the workpiece is inspected to ensure it meets the required specifications. This may involve measuring dimensions, surface roughness, and other quality parameters.

More than being a process that meet the required standard and known to design high-quality products, this process benefits from various advantages.

Indeed, precision grinding enables a high-precision with the achieve of tight tolerances and fine surface finishes. It is a versatile process that is suitable for a wide range of materials an shapes as well as ensuring consistent and repeatable results.

Therefore, grinding of the Rollix ring raceways guarantees the quality of the profile. This precision process also allows us to control the preload applied to our rings. Moreover, face and diameter grinding is possible to reduce run-out tolerances for high-precision parts.

To discover one of our processes in video: