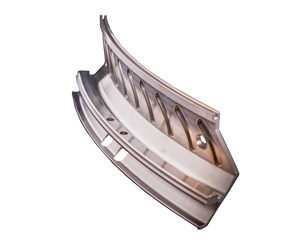

The Defontaine Group is one of the world’s leading manufacturers of complex parts for the aerospace and industrial markets and offers a wide range of flanges and sectors.

Our dimensional capabilities range from 150 mm to 6,500 mm in diameter. We work with the following materials: nickel-based, cobalt-based alloys, titanium, steel, stainless steel and aluminium.

Our expertise is recognised worldwide for both military and civil programs. We manage the entire supply chain from the supply of materials to the delivery of finished parts, including quality control of the production process.

Flash-butt welding

Flash-butt welding Precision machining and grinding

Precision machining and grinding  Press quenching

Press quenching Induction heat treatment

Induction heat treatment  Special processes

Special processes