Rollix design office: at the heart of innovation & creativity

Our Rollix design office is much more than a department. It is the heart of our innovation and creativity.

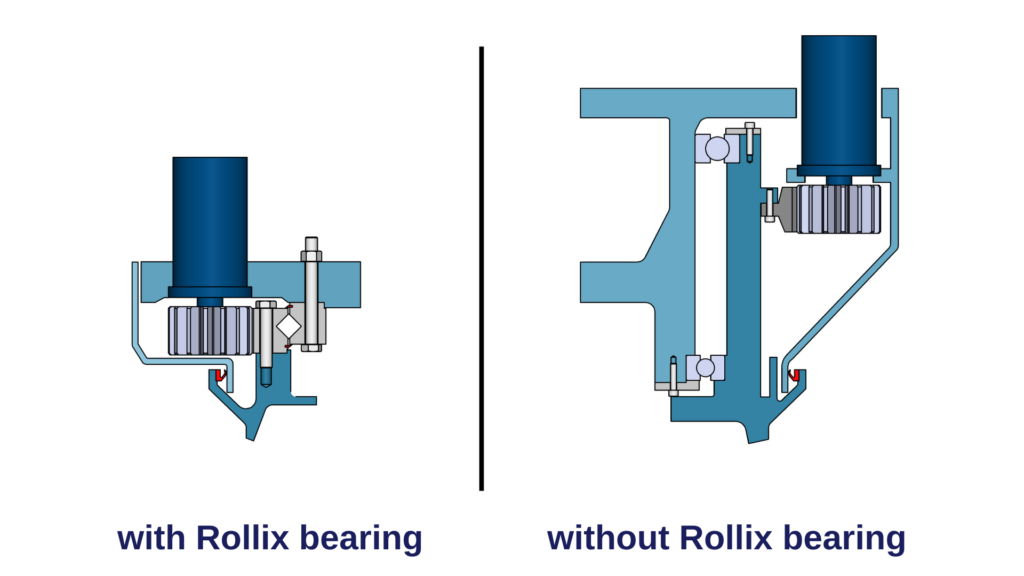

Why Rollix is the best choice for a slewing Ring?

- Fewer parts

- Less weight

- Less space

- Quick installation

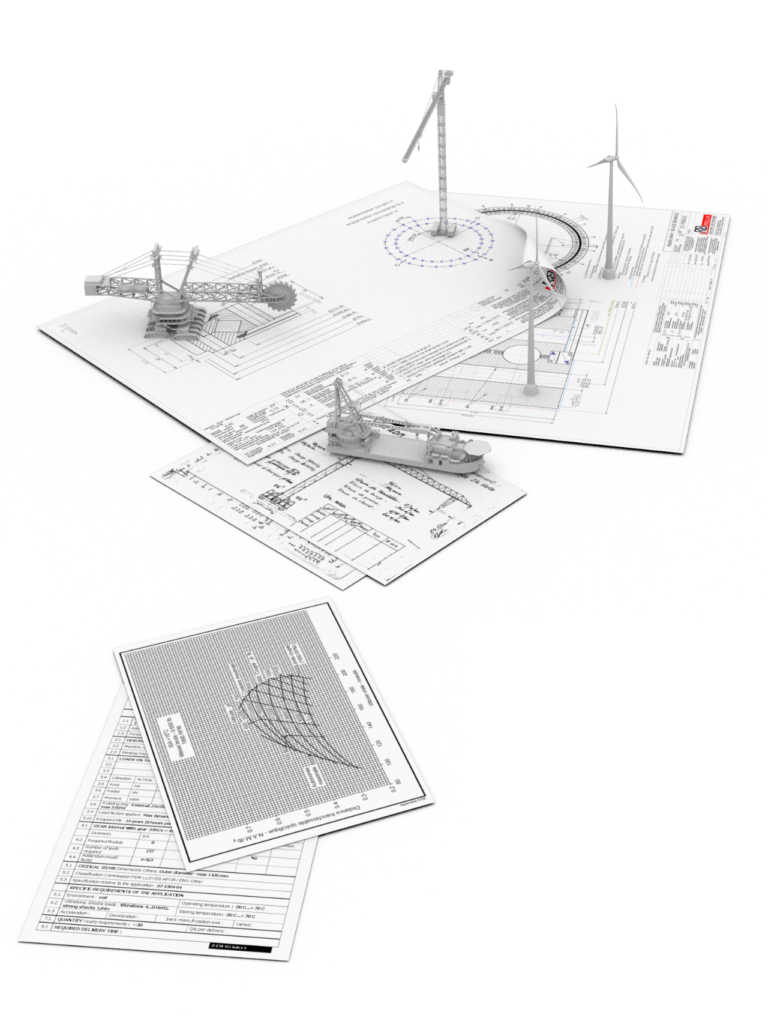

Study & design

Would you like to carry out your industrial projects?

Our team of experts is ready to meet the challenges. We put our industrial environment know-how and production processes at your disposal to design tailor-made solutions.

The process starts with technical study and then evolves into 3D designs and definition drawings.

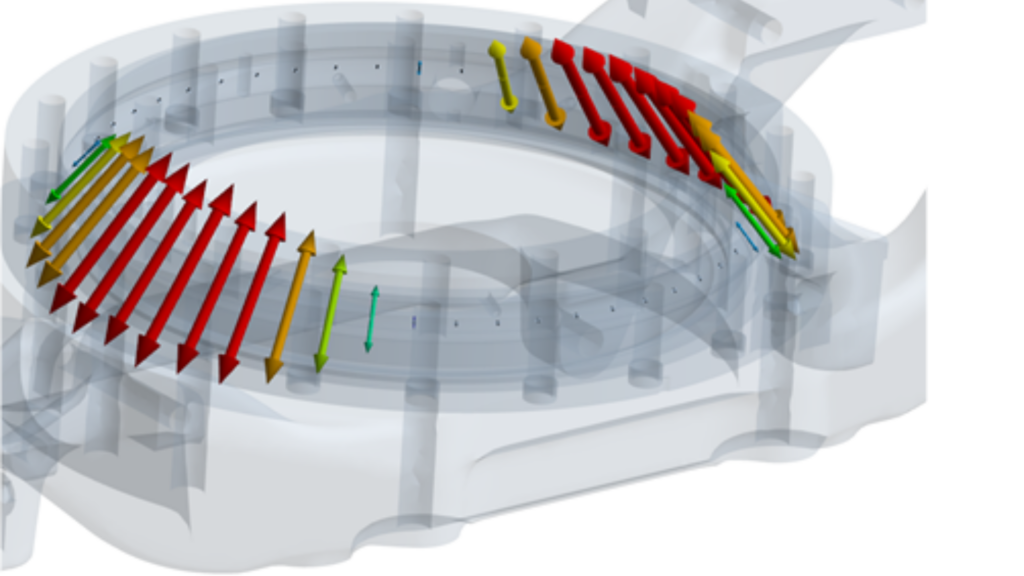

Finite Element Method (FEM)

If needed, FEM can be used to evaluate the load distribution in rolling elements, stress and deformation on rings and interface.

Rollix test benches

We developed ourselves test benches to validate our products for demanding sectors such as wind energy, machine tool, forestry, packaging and many others. These test benches, recognised by our customers, are essential for guaranteeing the optimum strength of our slewing rings:

– Test rig dedicated for slewing rings static capacity and lifetime

– Rolling elements test rig

– Lubricants test rigs

– Specific test rig 1 :1 for wind turbine

– Other test rig facilities (noise, sealing, torque, stiffness, greasing systems, new bearing technologies…)

Certifications

When required, several certifications levels can be achieved:

-Design approval

-Raw material certification

-Bearing manufacturing certification

Every detail counts. With our design office, ours customers are in good hands!

14 March 2024