Rollix, the gear cutting expert

The Rollix brand is proud to offer its gear cutting expertise to meet the highest quality standards in the industry. That is why Rollix is an exceptional choice, and why you should discover its capabilities and know-how that make it a leader in the field.

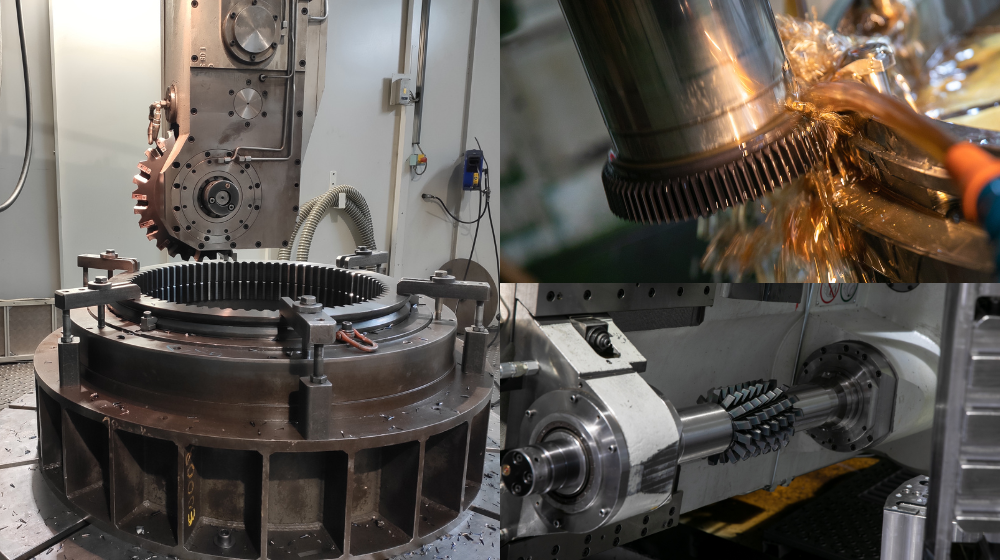

As well as being an expert in this field, Rollix offers three different processes for cutting internal or external, straight or helical gears (for external gears only):

- Gear gashing or gear milling : Gear is machined tooth by tooth using a milling tool. We can use specific insert, or sharpened inserts obtained by using a CNC sharpening machine.

- Gear shaping: gear tooth are shaped by cutting them by a multipoint cutting tool, a gear shaper

- Gear hobbing: gear is cut by a generating process by rotating the gear blank and the cutting tool at the same time with a fixed gearing ratio between hob and gear blank. The tool is a cylindrical cutting tool with multiple gear, called « hob ». This process can be applied for outer gear only (straight or helicoïdal).

Furthermore, Rollix capacity goes from Ø150 mm to 6000 mm and from Module 1 up to Module 30. We can even reach gear quality 7 or 8 according to ISO 1328 (or even Quality 5 or 6, with grinding).

With its leading expertise, Rollix is a suitable and trusted partner for quality gear adapted to a large panel of industrial applications.

For any request, contact us: https://www.defontaine.com/en/contact/

To have more information about our processes: https://www.defontaine.com/en/processes/