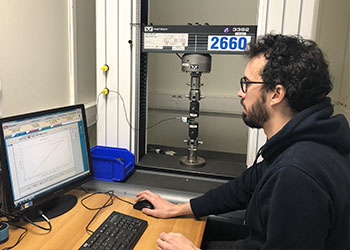

Our experts will provide advice and offer technical support to find the spare blade bearing adapted to your needs.

Rollix is the leader in this technology, and offers a very large stock of spare parts for the industry and for all wind turbines manufactured worldwide: Vestas / Siemens Gamesa / GE / Alstom, etc.

Let us know how we can help you, we will be happy to answer any questions.

DOWNLOAD THE BROCHURE

Responsiveness of

our teams

Availability of

our products